CRITICAL Global Supply Chain Crisis: How Political Turmoil Drives MASSIVE Inflationary Pressure by 2026

The Fragile Global Ecosystem

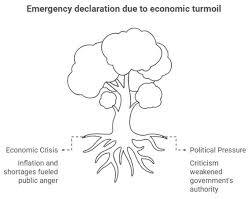

The world’s dependence on vast, interconnected global trade networks has never been more pronounced, yet this finely tuned system is currently operating under extraordinary stress. Geopolitical tensions—ranging from escalating regional conflicts to the rise of trade protectionism—are causing profound disruption to the movement of goods across continents। This convergence of political instability marks the onset of a new, prolonged Global Supply Chain Crisis.

The crisis is far-reaching, impacting every economic sector, from the availability of advanced consumer electronics to the cost and supply of essential commodities. The inherent fragility of the ‘just-in-time’ inventory model, which minimizes warehousing costs, is now being ruthlessly exposed by the unpredictable nature of Political Turmoil Impact on international commerce, creating systemic volatility.

Political Turmoil’s Direct Impact on Shipping and Manufacturing

The most immediate cause of the current widespread commercial bottleneck is the imposition of targeted trade sanctions, coupled with the intentional or consequential blockage of key international shipping routes. Vital maritime passages, responsible for moving trillions of dollars in goods annually, are experiencing severe delays due to drastically heightened security risks, compelling shipping companies to reroute vessels. This unprecedented disruption is a major contributing factor to the escalating Global Supply Chain Crisis.

In parallel, the manufacturing sector is enduring painful production stalls. Nations heavily dependent on raw materials from conflict zones are witnessing their assembly lines slow down. This has generated a critical scarcity of essential intermediate goods, such as specialized semiconductor chips, which, alongside labor shortages, confirms the deep reach of the Political Turmoil Impact on industrial output. Managing this complex situation is now central to navigating the current Global Supply Chain Crisis.

The Economic Fallout: Inflationary Pressure on Consumers

The most tangible, immediate, and painful result of these supply chain disruptions is the steep, unavoidable rise in operational costs, translating directly into massive Inflationary Pressure on household budgets worldwide. When the cost of transporting a single container triples or quadruples, manufacturers pass those inflated costs down the chain, meaning prices are rising for nearly every finished product available on the shelves. Successfully resolving this massive Global Supply Chain Crisis is critical for stabilizing the world economy.

Moreover, the Political Turmoil Impact on the global energy sector is a compounding factor. Geopolitical risks directly influence the stability of oil and natural gas production, causing extreme price volatility in global energy markets. Since almost all global transportation relies heavily on fuel, the subsequent increase in energy costs contributes significantly to the core inflation rate, challenging traditional monetary policy responses. This complex interplay of factors is what defines the current Global Supply Chain Crisis

The Way Forward: Resilience and Diversification

Successfully mitigating this ongoing Global Supply Chain Crisis demands profound, long-term strategic adjustments that extend far beyond simply hoping for political tensions to subside. The immediate industry focus has now shifted decisively toward building systemic resilience, redundancy, and risk mitigation strategies into the supply network. One major trend driving this shift is regionalization, where multinational corporations are actively moving critical manufacturing and sourcing closer to their final customer markets (a strategy often referred to as near-shoring or re-shoring). This move is designed specifically to reduce reliance on vulnerable, long global shipping routes, making trade flows less susceptible to sudden geopolitical disruptions.

In parallel, businesses are being compelled to hold larger inventory buffers (stockpiling components and finished goods) to absorb and cushion against the sudden shocks of future political instability, which inevitably increases warehousing and operational costs. On the technological front, companies are investing heavily in predictive Artificial Intelligence (AI) to anticipate potential bottlenecks, allowing them to reroute shipments proactively. Successfully navigating the ongoing Global Supply Chain Crisis is now a top priority for corporate boards globally.

Conclusion: The Enduring New Reality

The current climate of heightened geopolitical risk strongly indicates that the historical era of smooth, low-cost, and perfectly predictable global trade may be permanently over. The Political Turmoil Impact is no longer an occasional anomaly but a consistent, systemic factor that must be priced into every business model, from giant manufacturers to local retailers. The ongoing Global Supply Chain Crisis demands a complete rethinking of international logistics.

As the world attempts to decentralize and build a far more resilient trade network in response to these continuous crises, consumers must unfortunately prepare for sustained Inflationary Pressure. By forcing an overdue reckoning with the fragility of globalization, the Global Supply Chain Crisis is not just a temporary challenge; it is fundamentally redefining how and at what cost goods will be manufactured and delivered across the globe for the next decade.